Transform Your Manufacturing Tomorrow

Data-Driven Factory Optimization Through Proven Engineering Excellence

We help leading manufacturers improve productivity by 40-50%, reduce costs by 30-40%, and optimize operations through our proprietary PQRSTU-VWX-Y methodology.

Begin Your TransformationWhy Leading Manufacturers Choose S&H DESIGNS

Proven results across 200+ projects worldwide

Real Results - Performance Improvements

Measurable impact across key manufacturing metrics

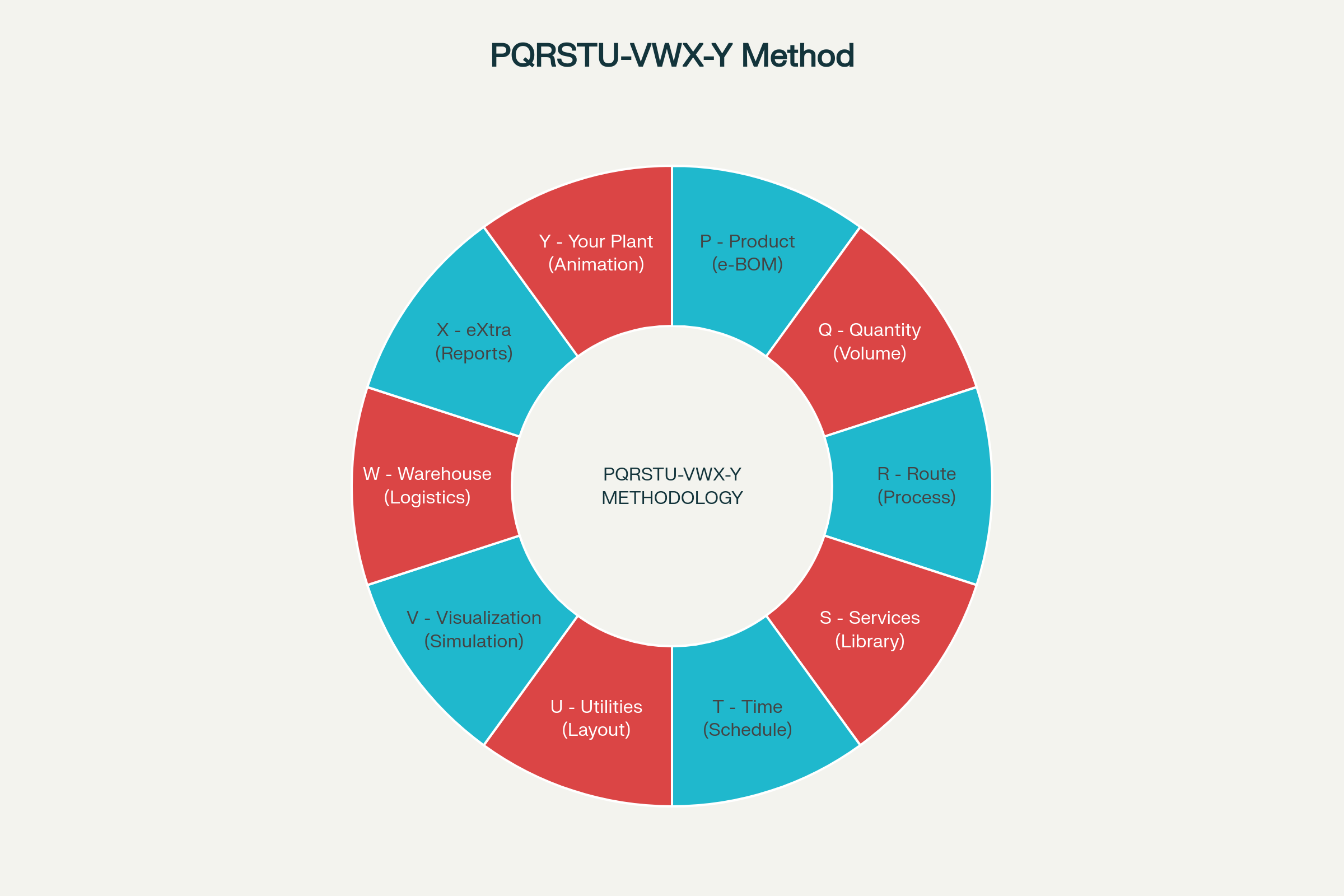

The PQRSTU-VWX-Y Methodology

A Complete Circular Framework for Manufacturing Excellence

Product

Product Information & Component analysis

e-BOM, m-BOM Development

Quantity

Production Volume Analysis

Annual production requirements

Route/Process

Process Flow Definition

Process mapping, VSM, Line Balancing

Services/Library

Equipment & Resources

Tools, fixtures, and machinery list

Time/Schedule

Project Timeline

Detailed project scheduling

Utilities/Layout

Layout Design

Footprint planning and space design

Simulation

Virtual Factory

Man/Machine/Movement simulation

Warehouse

Logistics Design

Warehouse and stores optimization

Extra Reports

Documentation

Final result documentation

Plant Animation

3D Visualization

Bird eye view and walk-through

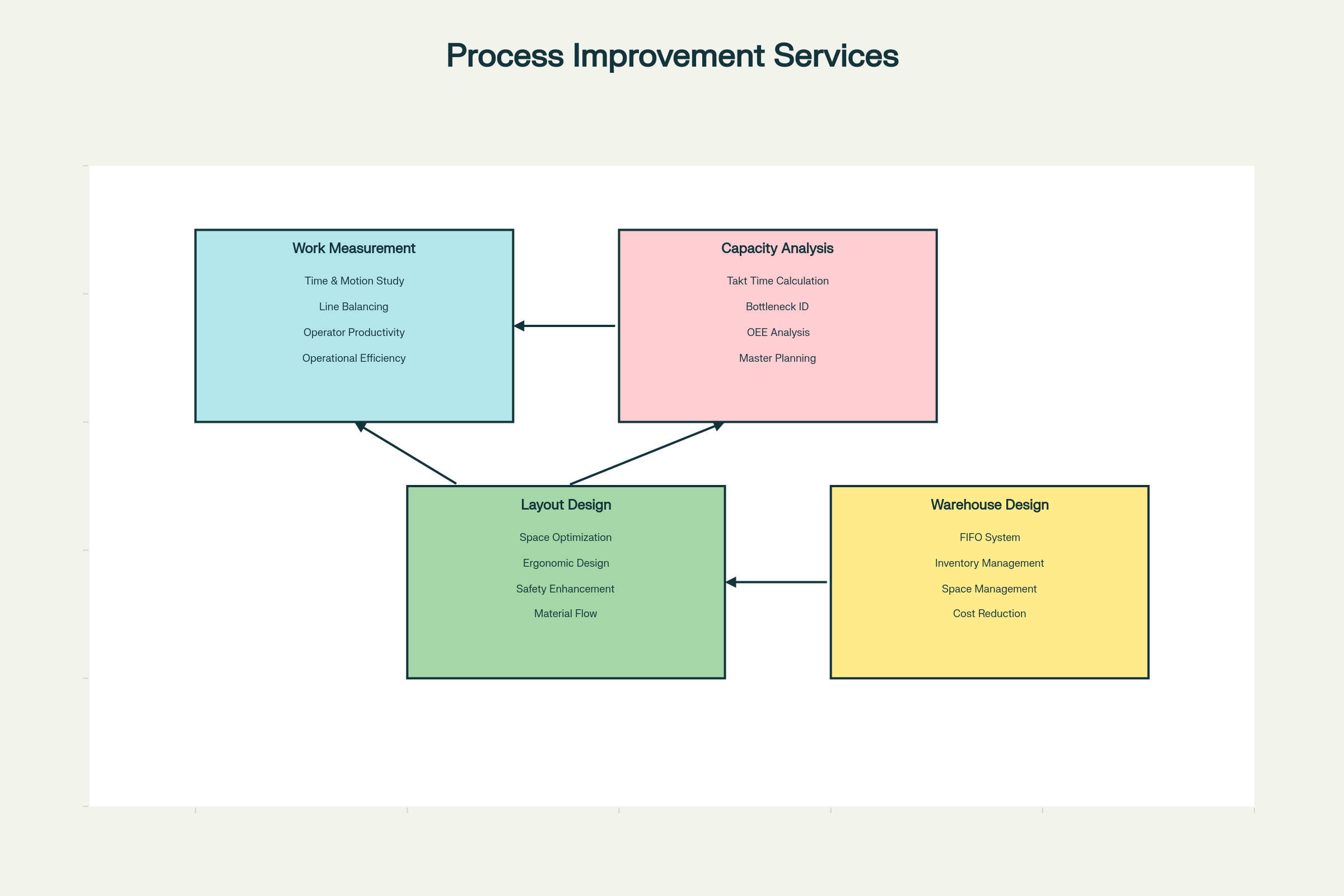

Our Four Core Services

Comprehensive process diagram showing our main service offerings

Work Measurement

- Time & Motion Study

- Line Balancing

- Standard Time Calculation

- Operator Productivity Improvement

- Operational Loss Minimization

Capacity Analysis

- Takt Time Calculation

- Bottleneck Identification

- OEE Calculation

- Capacity Enhancement

- Factory Master Planning

Layout Design

- Space Optimization

- Product/Process Layout

- Ergonomic Workstations

- Safety Enhancement

- Material Handling Minimization

Warehouse Design

- Space Management

- FIFO Implementation

- Inventory Management

- 2 Bin System

- Truck TAT Optimization

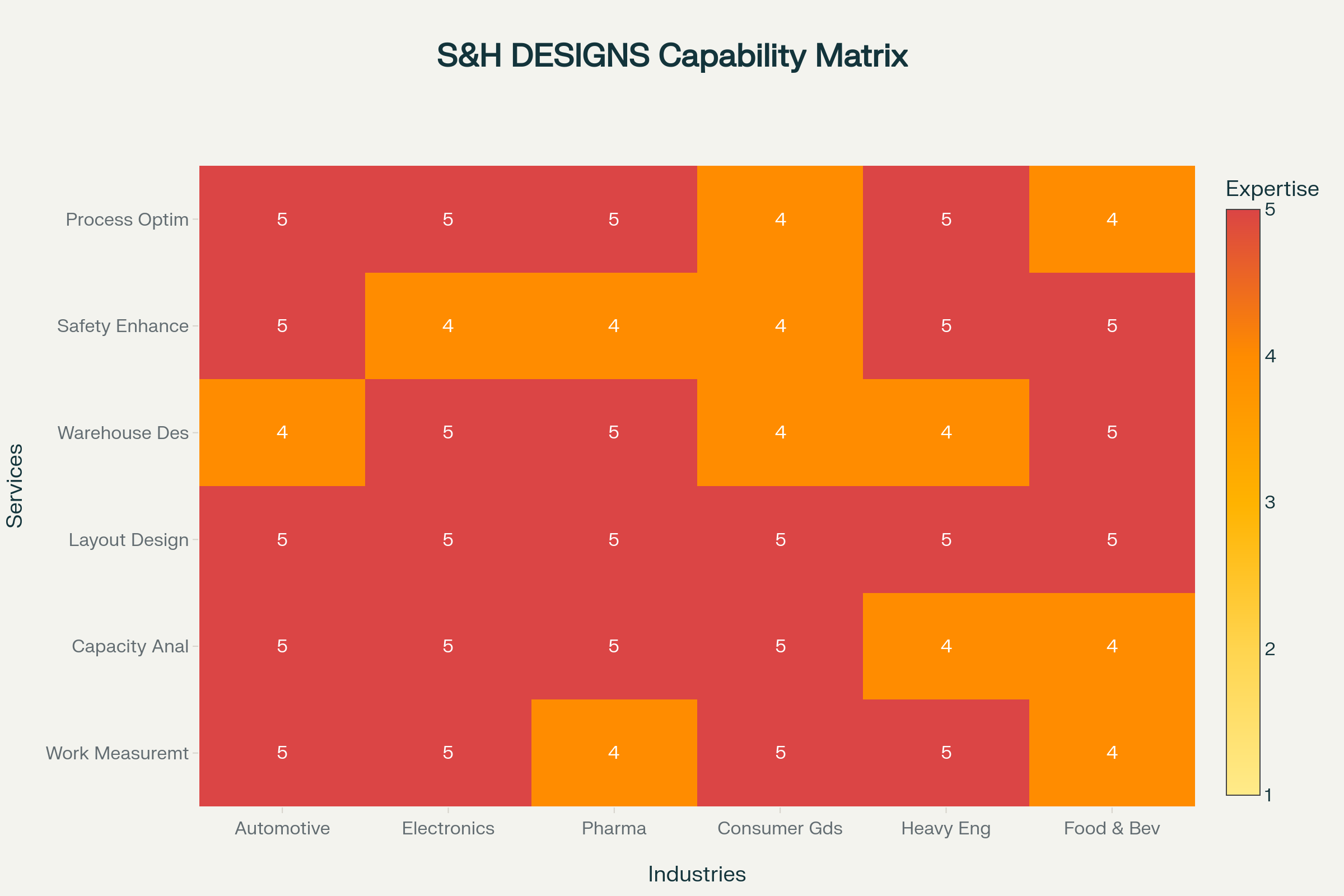

Our Comprehensive Industry Expertise

Deep expertise across services and industries

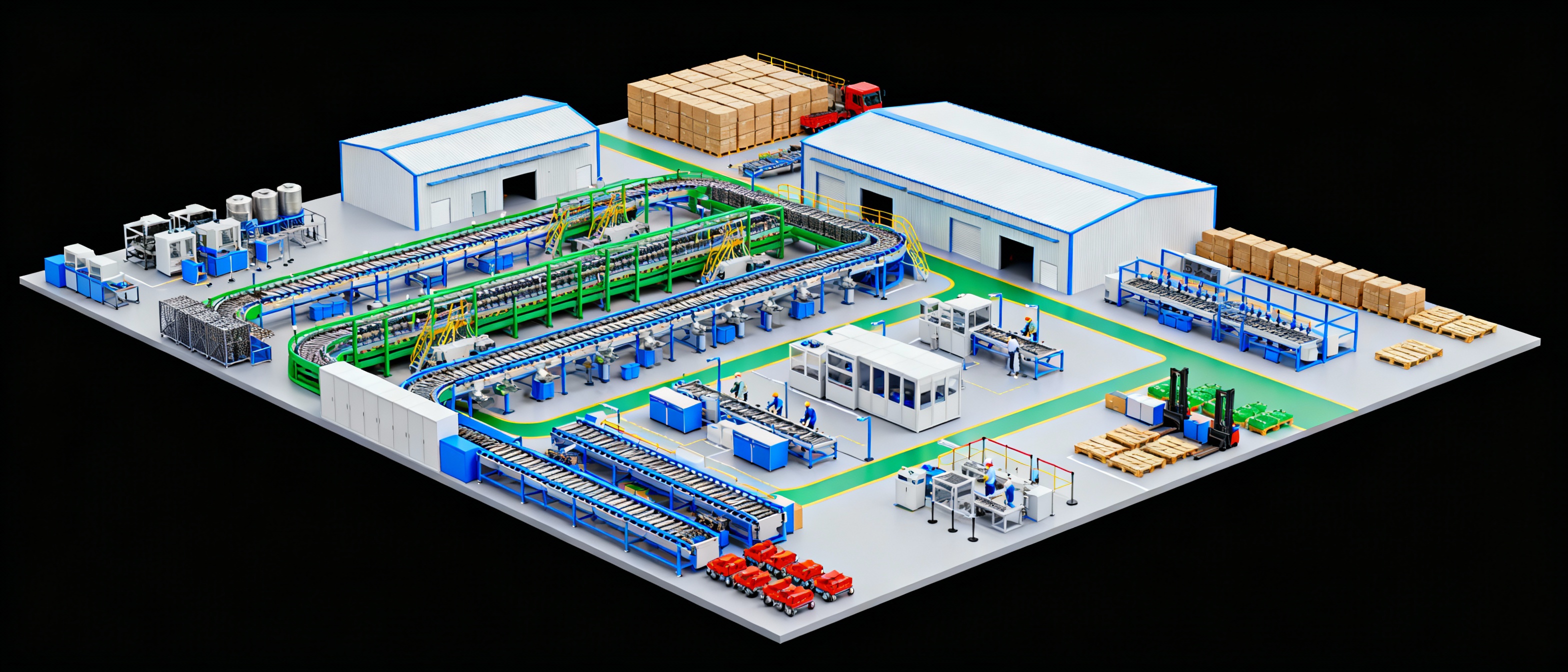

Our Visualization & Design Capabilities

Professional imagery showcasing our engineering excellence

3D Isometric Factory Layout

Complete facility visualization showing optimized manufacturing zones and workflow integration.

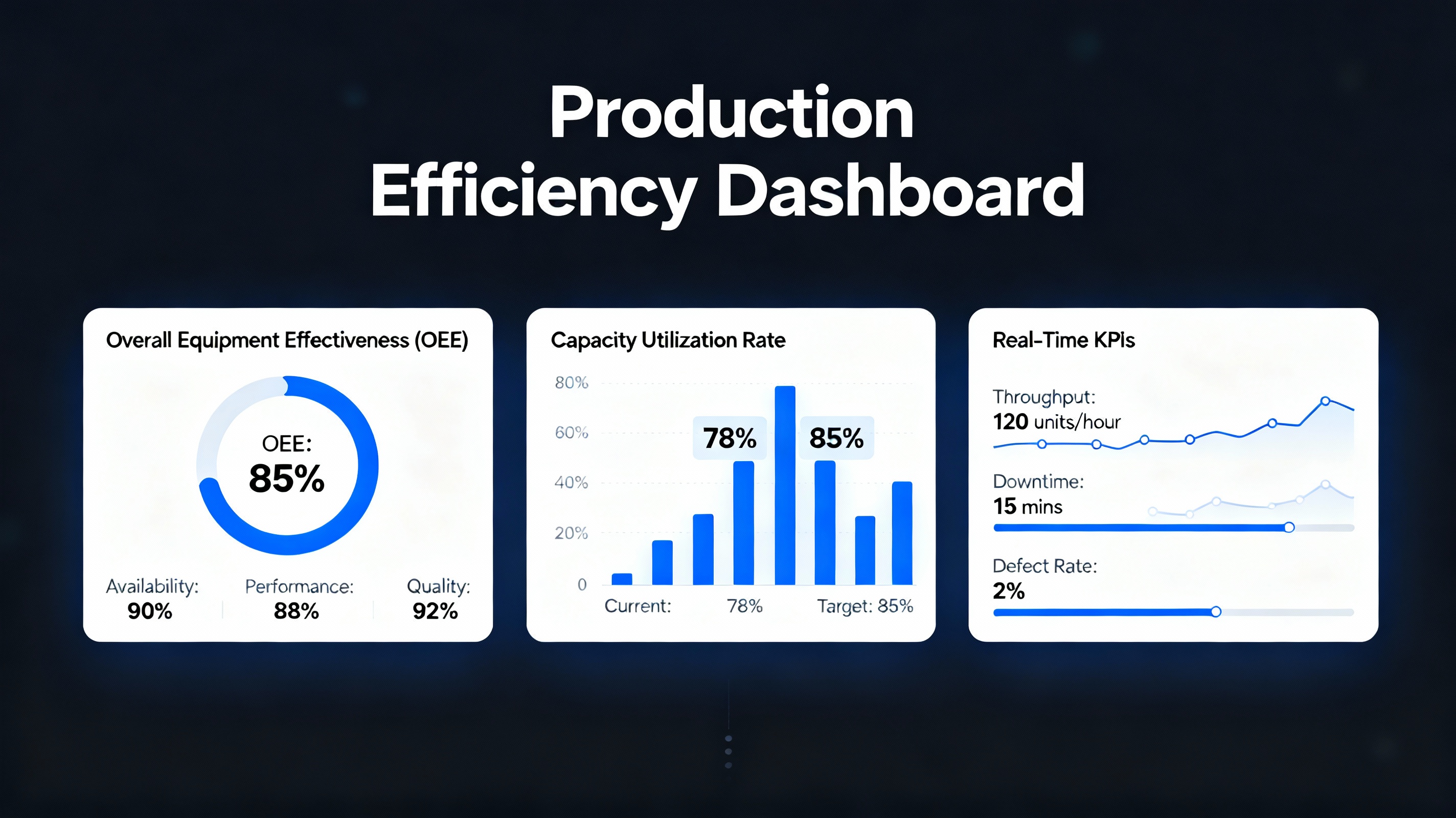

Analytics Dashboard with KPIs

Real-time production metrics dashboard for data-driven decision making and performance tracking.

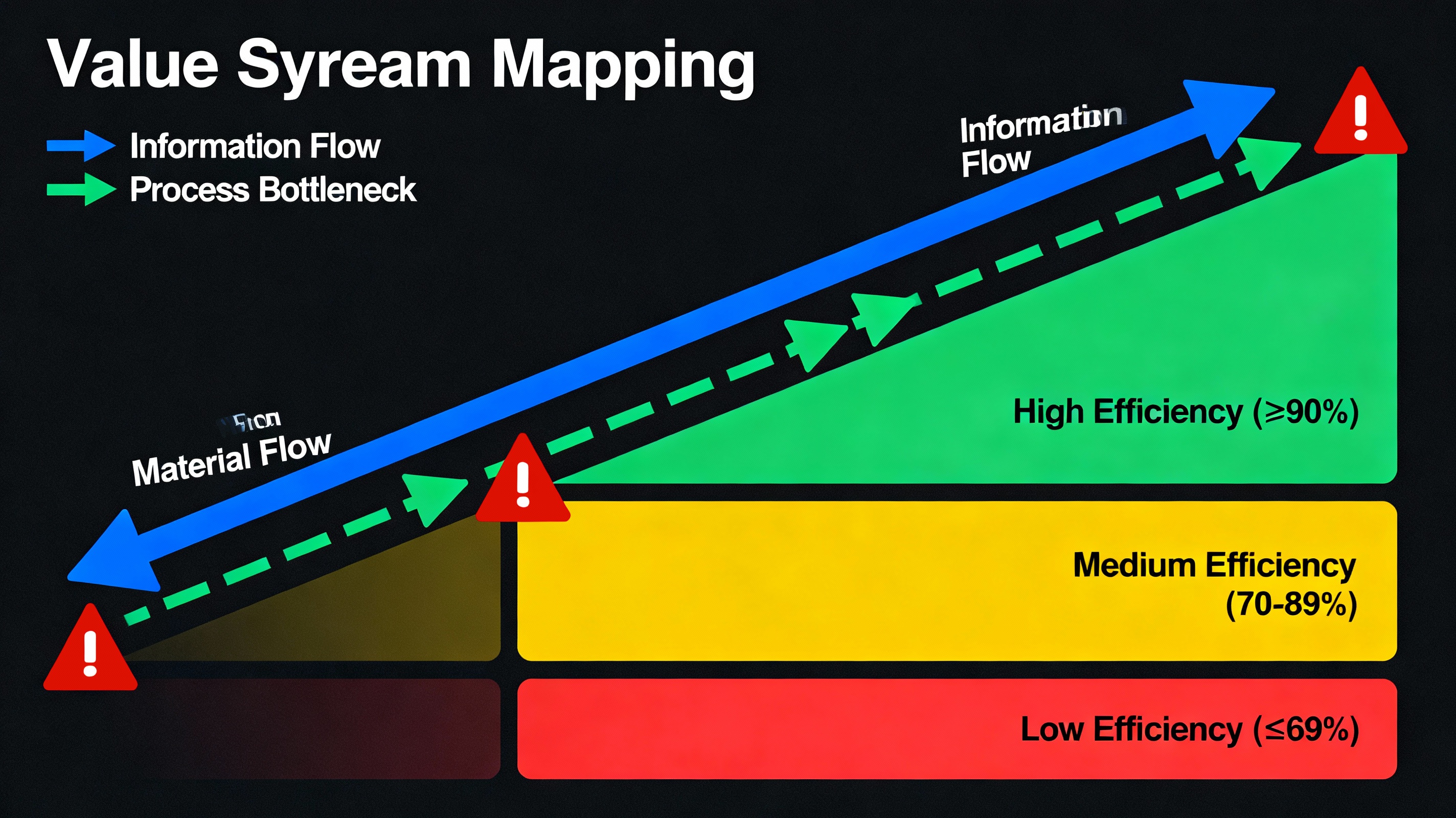

Value Stream Mapping

Comprehensive process visualization identifying waste and optimization opportunities.

3D Factory Automation

Photorealistic 3D animation showcasing automated manufacturing systems and robotics integration.

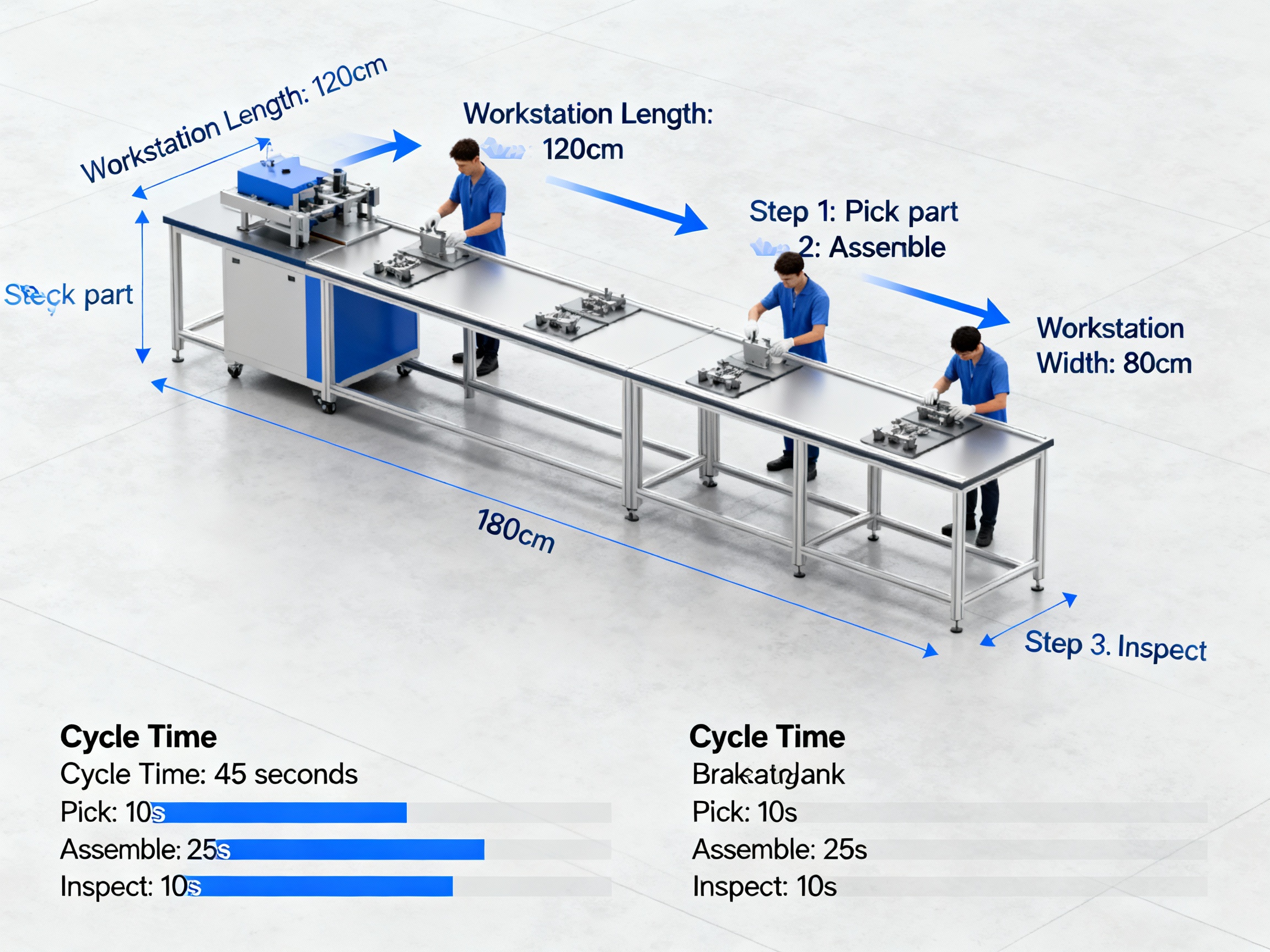

Time and Motion Study Analysis

Detailed motion analysis for productivity enhancement and ergonomic workstation design.

Aerial Facility View

Bird's eye view of color-coded manufacturing zones and optimized material flow paths.

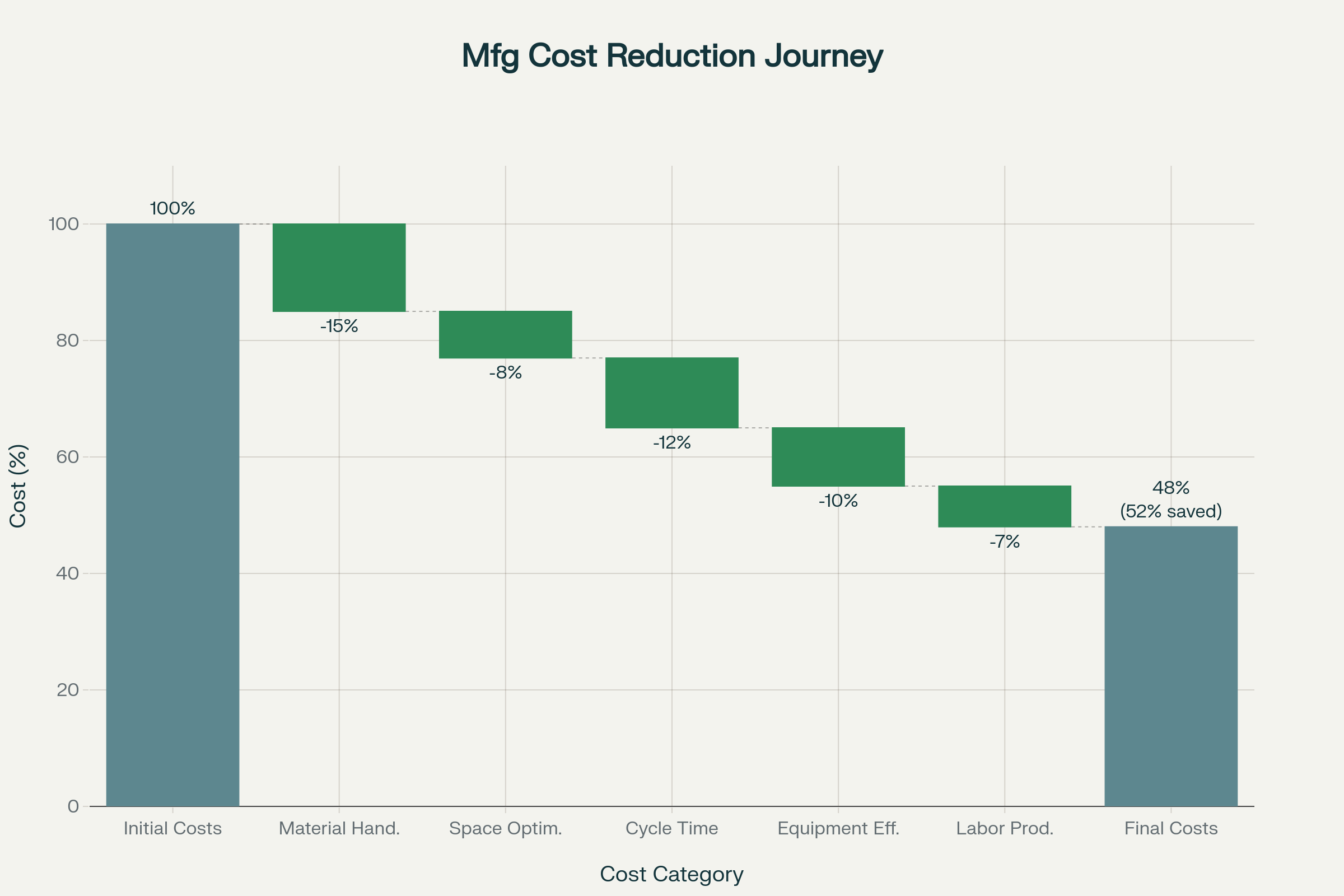

Cost Reduction Through Systematic Optimization

See how every area contributes to bottom-line savings

Warehouse Optimization Success Stories

Visual comparison of our transformation results

Before Optimization

- Vertical storage creates falling product risks

- Time-consuming searches in pallet racks

- Frequent part location changes

- Inefficient aisle space usage

- Forklift dependency and safety issues

After Optimization

- Horizontal storage eliminates falling risks

- Unique sized location for each reference

- Maximum storage density achieved

- Optimized surface area utilization

- Improved safety, eliminated forklifts

- Faster response to customer demand

What You'll Deliver

Complete Set of Professional Outputs

2D Layout Plans

Detailed AutoCAD drawings of facility layout with precise measurements and specifications.

3D Micro-level Layout

Comprehensive 3D visualization showing every detail of your manufacturing space.

Virtual Factory Simulation

Dynamic simulation using AnyLogic and Factory IO for process validation.

Value Stream Mapping

Complete VSM analysis identifying waste and optimization opportunities.

Digital Standard Operating Procedures

Interactive SOPs with step-by-step work instructions and visuals.

Line Balancing Reports

Detailed analysis showing workload distribution and efficiency improvements.

Takt Time Calculations

Precise timing analysis ensuring production meets customer demand perfectly.

Plant Animation

Photorealistic Blender animations with bird's eye view and walk-through.

Warehouse Optimization

Complete warehouse redesign with FIFO, space management, and flow optimization.

Factory Master Plans

Comprehensive planning documentation covering all aspects of the transformation.

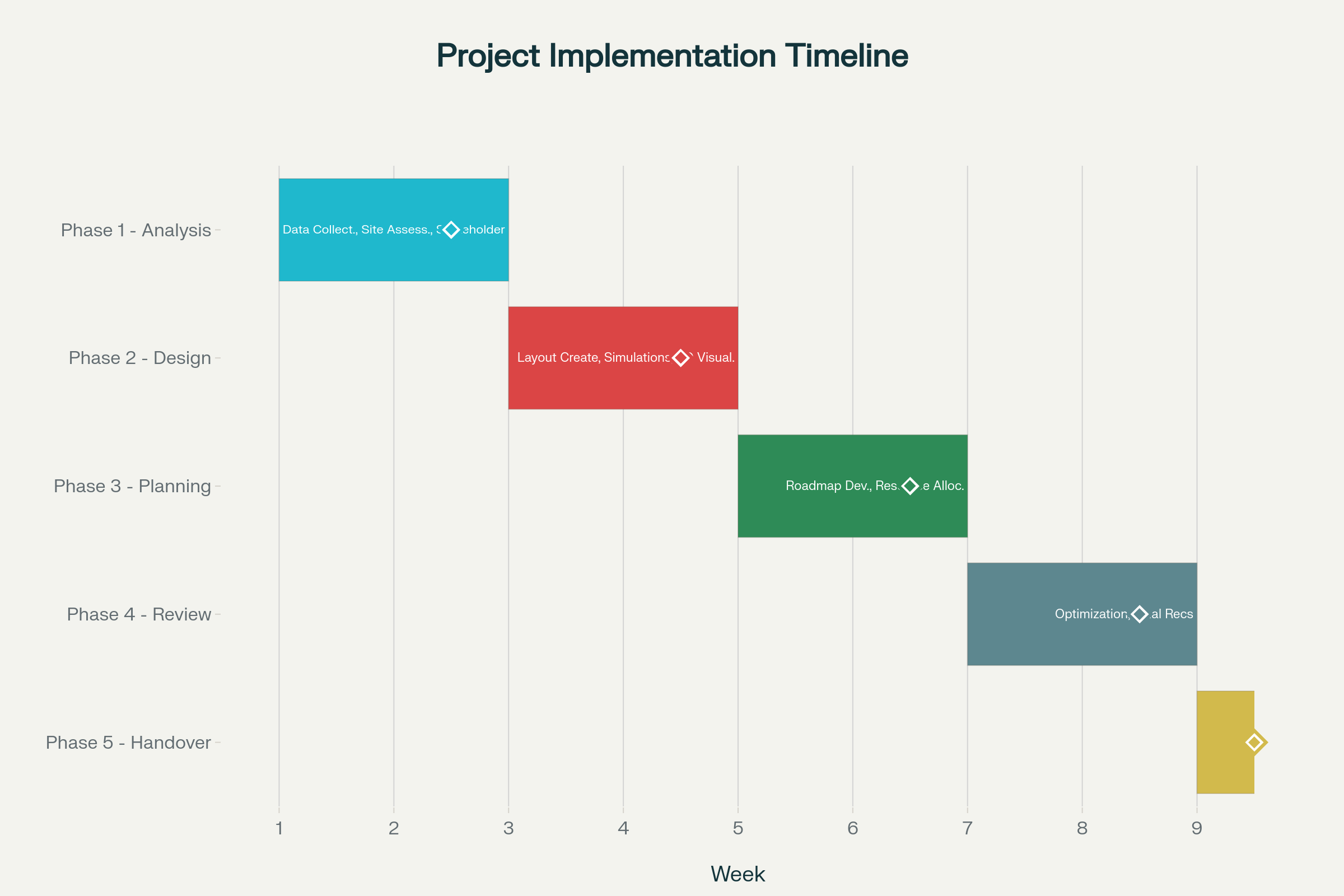

Your Transformation Journey

5-Phase Implementation Approach

Analysis

- Site assessment

- Data collection

- Stakeholder interviews

Design

- Layout creation

- Simulations

- 3D visualization

Planning

- Implementation roadmap

- Resource allocation

Review

- Final recommendations

- Optimization adjustments

Handover

- Documentation

- Training

- Knowledge transfer

Measurable Benefits

Quantifiable improvements you can expect

Space Optimization

Optimize space utilization and reduce operational costs significantly

Enhanced Efficiency

Systematic layout design improves production efficiency

Safety & Ergonomics

Minimize material handling and improve workplace safety

Capacity Increase

Increase capacity and reduce production bottlenecks

Cost Reduction

Reduce material handling time and transportation costs

Streamlined Operations

Optimize warehouse and inventory management

Technology Tools We Use

Industry-leading software for professional deliverables

AutoCAD

Professional layout drawings and blueprints

AnyLogic

Virtual factory and process simulation

Factory IO

Interactive factory visualization

Blender

Photorealistic plant animations

PowerPoint & Excel

Reports, analysis, and presentations

Get In Touch

Ready to transform your manufacturing operations? Contact us today

Contact Information

Address

B-11, Paramnavnath Park,

Shivtirthanagar, Kothrud,

Pune 411038, Bharat

sales@shdesigns.in

Phone

+91 79720 53255